A Guide to Selecting Pneumatic Conveying Elbows

Solve problems like shredding, streamers, blocking and dusting, friability, and more.

Selecting Elbows for your Pneumatic Conveying System

If you have a pneumatic conveying system, you’ve probably experienced elbow wear problems like shredding, streamers, blocking and dusting, pile and bulking, contamination, downtime, friability, corrosion, and erosion, not to mention the associated costs.

Using abrasion-resistant solutions such as specialty elbows that fit your existing system can minimize downtime and reduce wear. But why and when should you use specialty elbows in your pneumatic conveying system?

Just as there are many different applications, there are also many different types of elbows in pneumatic conveying. While this article doesn’t aim to cover every variable in the elbow selecting process (and there are considerations not discussed here like pressure, temperature, and corrosion), we hope that this guide will help think critically about what your system is telling you, to find a solution that fits.

Read on for detailed information on different elbow types and solutions as well as guidance on how to select the one that’s right for you.

Table of Contents

How to Select Pneumatic Conveying Elbows

Given that pneumatic conveying has been around for more than a century, something as simple as choosing bends for a system should have long become a routine task. However, engineers still commonly misunderstand the significance of choosing the right pneumatic conveying elbow. This lack of industry-specific information about an important component in the system has consequences. Haphazard usage of the wrong type of elbow often plays a role in system pressure drop, system wear, and product degradation. Given the confusion that arises when seeking the best elbow, this article seeks to help designers and users make better decisions on the proper conveying elbow to use for their unique manufacturing needs.

Common Elbow Types

There are a number of variables that affect the efficiency of bends in a system. However, the one that has the biggest effect is the style of elbow selected. There are three main types of elbow: long radius elbows, short radius elbows, and impact/vortex elbows.

Long Radius Elbows

The most common elbow for conveying material is the long radius elbow. A long radius elbow is any elbow whose centerline radius is 10x (or longer) than the outer diameter of the elbow. For example, a 4-in. tube elbow would have a centerline radius of at least 40 inches. The original industry standard was a 12x radius because it corresponded to 1ft in radius, and this is method is still sometimes used because it makes the math easy. A 2-in. pipe would need a two-ft radius, 3-in. pipe would need a 3-ft radius, 4-in. pipe would need a 4-ft radius, and so on.

Short Radius Elbows

The next most common elbow is the short radius elbow. These elbows are similar to long elbows but have shorter radii, typically 2.5 to 4 times the outer diameter of the elbow. There are also short radius “weld-fitting” type elbows. They are 1 to 1.5 times the elbow diameter. However, these elbows are usually too tight; they are not typically used for pneumatically conveying product.

Impact or Vortex Elbows

The last category of elbow is the impact or vortex elbow fitting. These short fitting-style elbows protect themselves from abrasion by mechanical means. Dead-end (or blind) tees and vortex style elbows fall into this category.

Pros and Cons of Different Types of Elbows

Short radius elbows have many advantages. They are readily available, less expensive, lighter, easy to install, easy to replace, and take up a lot less space. For some applications, they can be the perfect elbow. However, they do have some major disadvantages, too. Short radius elbows – which have a severe angle of impact – take a lot of punishment in one spot just off the centerline of the elbow, making them more likely to blow out if the product is abrasive. Additionally, the greater impact in short radius elbows often contributes to greater product degradation.

Long radius elbows, by comparison, are more difficult to handle but offer some innate wear protection. By having a shallower angle of impact – and allowing product to drag all the way along the back of the elbow – impact is reduced and wear spread more evenly down the back of the elbow. Product degradation is also reduced when compared to a short radius elbows. (The exception to this rule are products that smear and/or create streamers, like polyethylene pellets. These applications have a worse time with degradation because of the amount of time they spend dragging the back of the elbow. When this happens, an elbow with a grooved/surfaced interior or a fitting/specialty elbow is used). As a final consideration, some products could bounce and cause multiple wear points in a long radius elbow. This problem is rare in dilute phase conveying. When it does happen, it can be avoided by using a short radius or impact elbow, but it then usually results in the bounce still occurring and wearing out pipe on the outlet side of the elbow instead of the elbow itself.

Impact elbows are the dead-end tee (blind tee) and the vortex style elbow, both of which work well to minimize abrasion and product degradation. Moreover, the dead-end tee also has the extra advantages of being readily available and inexpensive. However, neither elbow should be used if the products are moist, cohesive, or sticky. Also – and we should acknowledge that there is conflicting data and opinions on this point – using these elbows may have an adverse effect on system pressure and conveying efficiency in some situations. While this is not a reason to avoid impact elbows, use caution before changing out a bunch of radius elbows for impact elbows in an existing system.

Choosing an Elbow to Suit Your System

So now you know the pros and cons of different elbows, how do you decide which is the best elbow for you to use? That all depends on your problem. If you have an abrasion problem, then there is no one best solution. There are many effective answers for abrasive applications; they come in all different price ranges. Both short and long radius elbows have several direct replacement solutions: special coatings, tile elbows, replaceable back elbows, and channel back elbows – just to name a few. Direct replacements are great because they fit right in the same spot as the old elbows without any change in the convey lines. However – if you do not mind changing your system – impact elbows can also achieve effective results.

Considerations when choosing the right elbow for wear

Do not pay for a ‘better’ wear solution than you really need. Be sure to match up the cost of the wear solution against life of the elbow – and hassle of changing that elbow.

Bare long radius elbows offer some basic protection against wear. If there is very light wear, they can be a good alternative to bare short radius elbows. However, the cost savings of any wear protection gained needs to be measured against the extra installation costs of using a larger, heavier elbow (weight, space, support, etc.).

Remember that wear is a war of attrition. If you are getting two months out of a Schedule 40 pipe elbow, you will not even get four months out of a Schedule 80 elbow. Plan to use a different solution than just a thicker pipe.

A wear resistant elbow is only as good as its weakest point. Putting in a wear resistant elbow made of very thin walled tube material – or using threaded pipe ends – means that elbow will only be in the system for as long as it takes the tube to wear out underneath the compression coupling – or for the pipe threads to wear out.

Velocity is a killer. The elbow that wears out the fastest is usually the one in the system where the highest velocity occurs. Beware of elbows at the end of a long run of pipe.

Channel back (aka hollow-back) elbows can be quite effective. They protect against wear by filling up with product and allowing the product to wear against itself. However, do not use these in applications where the built-up product can spoil and cause contamination: applications like grain, food, or pet food.

Proprietary elbows like Ni-Hard bends and vortex elbows come in set standard degrees only, like 90 and 45 degrees. If you have some other degree, you will need to use a different solution for those bends.

A simple dead-end tee can be an elegant fix – and it is cheaper than a specialty vortex elbow. They also can do a great job acting as a target box right before dropping into a storage container.

Impact elbows often have problems wearing out immediately after the outlet due to turbulence. Using an abrasion resistant spool of pipe connected to the outlet is often very useful for minimizing the problem and allowing the changing of the piece quickly when it does wear out.

What if there are no abrasion problems in the system?

If you don’t have wear issues and product degradation is not a concern then the choice is clear: use a short radius elbow. There are too many cost and labor saving advantages to go any other way.

One last piece of advice regarding elbows in already operating systems… If you are happy with the amount of wear you are experiencing in your system, with particle degradation and system output, then don’t change a thing. As the saying goes, if it isn’t broken, don’t fix it. There are numerous variables that affect the efficiency of bends. Sometimes changing just one bend has unexpected consequences. If you are up for doing some research – and controlling all the variables while figuring out what optimizes your system – then great, do some experimentation. However, most production facilities who are more concerned about output and production consistency will appreciate leaving well enough alone.

Selecting a Specialty Pneumatic Conveying Elbow

Wear is one of the common problems in pneumatic systems. It is one that can cost extraordinary amounts of resources in labor and replacement costs. While there are many simple ways to select good elbows for a given system, sometimes there is a need to select a specialty solution.

Over the years of pneumatic conveying’s history, many people have developed various ways of handling the complex problem of wear. Just as there are many different conveying applications, there are also many different solutions. Each solution is geared toward solving a particular problem while remaining within the bounds of a set of constraints that are considered important. Obviously, the most common constraint is replacement cost, but there are also other important factors like elbow material composition, corrosion resistance, food contact concerns, ease of replacement, and system space. So, with all these different considerations – in addition to abrasion resistance – a review of specialty products and techniques is in order.

The first consideration when picking a replacement elbow is usually cost. But, because of the labor required in replacing pneumatic conveying elbows, ease of replacement often goes hand in hand with considering the cost of the replacement elbow. Therefore, the most popular solutions are ones that fit into an existing system just like the original sweep elbow. Following are some of these solutions.

Abrasion Resistant Elbows to Replace and Improve Wear

Replaceable-Back Elbow

The Replaceable-Back Elbow is a regular sweep elbow with sides welded on and a replaceable plate bolted on the back. It uses a similar “wear and replace” philosophy as the square elbow. Again, these can work great for mild abrasion problems. These elbows can be enhanced by using thicker plates on the back of the elbow or using AR steel material. This elbow doesn’t use transitions, so it doesn’t have the problem of wearing them out. However, they can have the problem of wearing out the sides before the top, compromising the structural integrity of the elbow. Furthermore, when the top of the elbow wears away there may be some open pocket areas between the round elbow and the square back. This may create an opportunity for materials to pack into that area. For this reason, food products and lines that convey multiple colors that contaminate should be avoided.

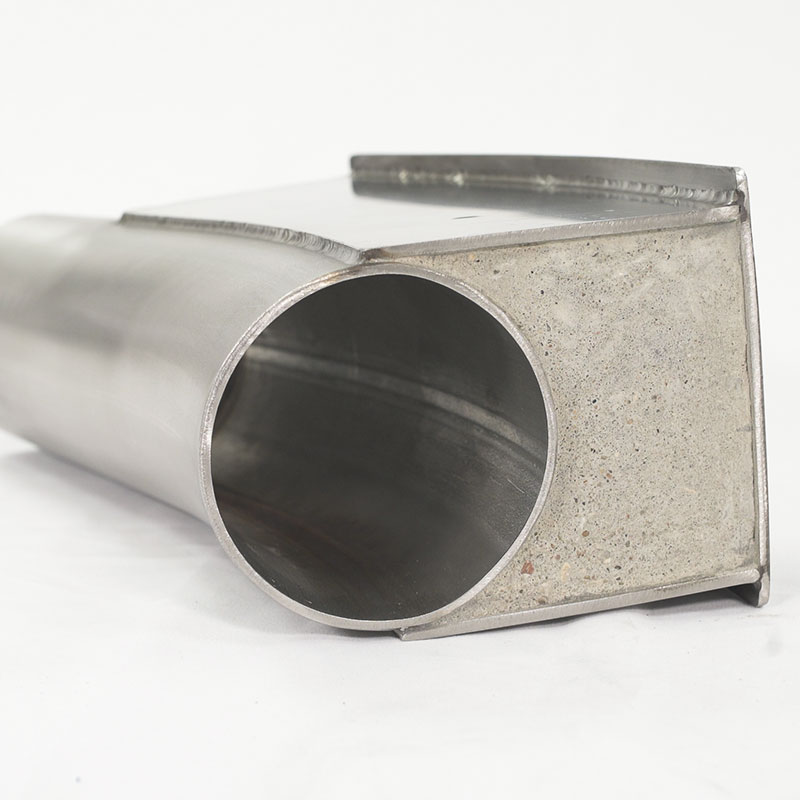

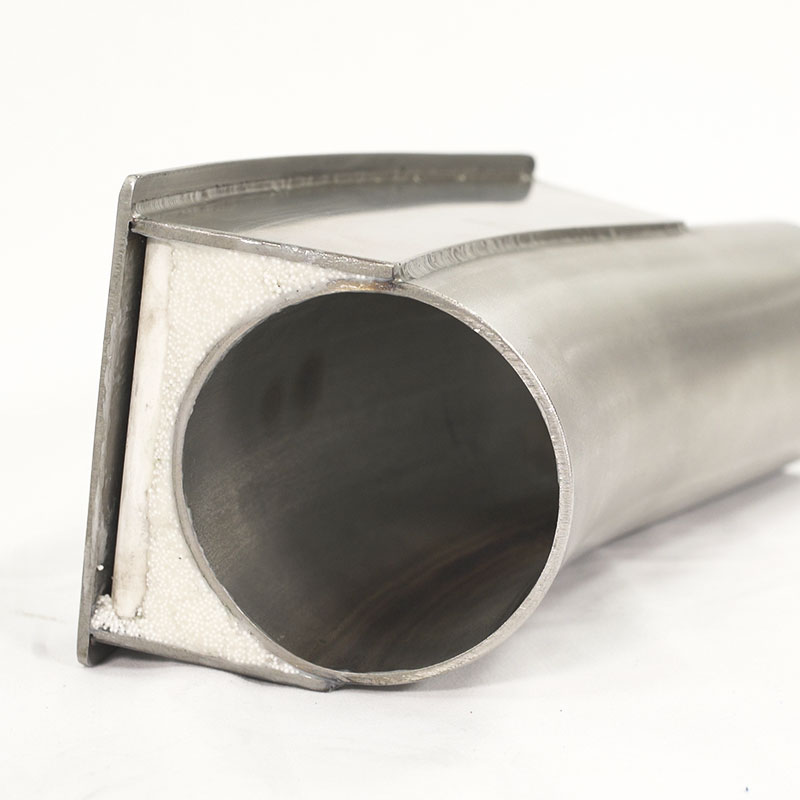

Hollow-Back Elbow

A Hollow-Back Elbow is exactly as it sounds. Either an empty square box or an open rounded channel is welded onto the back of a sweep elbow. Once material wears through the elbow, the cavity can fill up with the product and protect against abrasion by wearing against itself. This can work really well with extremely abrasive materials that tend to pack. How well the material packs into the cavity depends on the characteristics of the material, the velocity of the system, and the position of the elbow. Once again, because of the pocket area of the elbow that holds material, food and materials that can spoil or contaminate should be avoided.

Cement-Back Elbow

A Cement-Back Elbow is constructed like a Hollow-back elbow – except the cavity is filled with cement. For obvious reasons, these are most popular in the cement industry. While cement is not the hardest of substances, it still can be quite effective in heavy industrial applications.

Porcelain Lined Elbow (Ceramic Lined)

While these are sometimes marketed as ceramic lined elbows, they are not. Porcelain Lined elbows have an industrial porcelain lining fired into the inside of the elbow. This lining is only several thousandths thick. It protects by lowering the coefficient of friction inside the elbows and allowing the product to slide inside them. Additionally, industrial porcelain does possess some real abrasion resistance because of its hardness – a 6 on the Mohs scale – which is harder than mild steel. Furthermore, porcelain can offer some measure of corrosion protection. However, all provided protection is very thin and susceptible to cracking with hard impact. There can also be pinholes and imperfections in the kilning process. Because of this, they are not considered to be a food grade solution.

Ceram-Back® Elbow

The Ceram-Back® Elbow is a sweep elbow with a ½-in. of hard ceramic compound on the outside of the elbow. The idea is that the metal of the elbow is left to wear out then transfer the abrasion to the much harder ceramic material. The advantage of these elbows are they can offer ceramic protection to any size or centerline radius of elbow without mitering – something difficult for ceramic tile lining. The Ceram-Back® elbow also only offers protection where it’s needed – the back and sides of the elbow. They offer excellent protection for sliding abrasion. Ceram-Back® elbows can also be used in conjunction with other techniques such as taper boring, induction hardening, porcelain lining, and tungsten carbide lining. However, the downside is that they are not as good as ceramic tiles for protecting against large particle or heavy impact problems. They also have some heat limitations.

Ceramic- and Basalt-Lined Elbows

Ceramic- and basalt-lined elbows offer superior protection for almost any application. They are inherently impact resistant and offered in high-heat and corrosion resistant variations. The tiles used to line the elbows are offered from thinner protection – like ½ in. – to several inch-thick bricks. However, their construction can make them harder to get in smaller sizes and longer centerline radii. Additionally, it is not unusual for these elbows to have to use special oversized flanges to fit into a system because of the unusual size of the outer diameter of the elbow. Ceramic lined products also tend to have a longer lead times and are usually the most expensive of all the solutions.

Cast Ceramic Flat-Back Elbow

The Cast Ceramic Flat-Back Elbow has a box back on a sweep elbow – like a cement-back elbow. Instead of being filled with cement, it is filled with solid cast ceramic tiles. It has a heavy resistance to wear and impact. It can be easily patched on the outside, if needed, and it is much cheaper than a ceramic tile lined elbow. Furthermore, unlike a ceramic lined box elbow, it doesn’t have transitions that wear out or cause turbulence. It is also available in most sizes, in any degree, or in any centerline radius.

Solutions to Small Spaces: Short Radius Elbows

Sometimes space is a huge factor. For those who have systems that are short on space – or for those who don’t mind refitting their system – there are specialty elbows that come only in a short radius. Some of these solutions are the following:

Tungsten Carbide Clad Elbows

Tungsten carbide is an ultra-hard, abrasion-resistant metal coating applied to the inside of elbows. It has really excellent wear properties – particularly against sliding abrasion. However, because of the way it is applied, the coating is usually fairly thin and limited to shorter radii elbows. It should also be noted that tungsten carbide usually offers some corrosion protection.

Dead End Tee (Blind Tee)

These elbows mechanically protect against abrasion by filling one end with material that then protects from wear by having the product wear against itself. These tees can work really well in many different situations. However, they should not be used if the product is moist, cohesive, or sticky. Dead end tees are available in mild steel, abrasion resistant materials, and can also be ceramic coated.

Ni-Hard Bends

These are short radius elbows that are cast out of Ni-Hard alloy (around 600 Brinell). They are usually thick-walled, very tough, and good for high heat applications. Some of the elbows even have replaceable back designs. That said, they are fittings – so they are only available in short radii, and are limited in size and degree. Additionally, while Ni-Hard is tough, it is not nearly as tough as harder materials such as ceramic tile.

Vortex Elbows

Vortex elbows, such as the Progressive Products Aero-Back™, protect against abrasion by using mechanical means. They have a chamber in the back of the elbow that causes the material to spin into a vortex. This vortex deflects material and causes the material to move through the elbow in a way that reduces wear. This style of elbow is available in different materials and alloys. Some of these cast materials offer extra abrasion or corrosion resistance. There are, however, some definite limitations. There is a minimum amount of line pressure and product flow required for the vortex action to work properly. And, because they are fittings, they are limited to certain sizes, configurations, and degrees.

As this brief overview has shown, there are many different solutions available to solve wear in pneumatic conveying systems. Some are direct replacements, or fit in small spaces, and some are not. Some work well with high heat or corrosion, and some do not. There is no one solution that solves all problems. In pneumatic conveying, the best solution is always the one that fits the import criteria of a particular system and offers the best overall value for the customer.

4 Things To Consider When Choosing a New Pneumatic Conveying Elbow

Replacement elbow types are often high on manufacturers’ purchase lists and if you’re responsible for choosing a new elbow for your pneumatic conveying system, you have a few things to consider. One of the first things you may do is look at the upfront cost of a new elbow. Choosing the cheapest option may seem like the best idea at first, but if you need to replace multiple elbows more frequently it may not be cost-effective in the long-term. Upfront cost is only a small part of the picture.

Overall, it’s important to look at all the factors which contribute to the potential life-expectancy of a new elbow and will give you the best return on investment.

Cost of Materials and Labor

Depending on your system, replacing elbows once every two years with a higher quality, more expensive version versus multiple times per year with a cheaper version may work out to be more effective for both cost and labor.

From a cost perspective, you will be purchasing new elbows less frequently as the ones you use will be more durable, and this will also mean that you will not need as much resource in terms of labor.

Potential Downtime

When an elbow blows, the production line has to be shut down which could result in missed shipping schedules and deliveries. Depending on what you’re manufacturing, it may not be a simple matter to call everything to a stop.

Production line shutdown can happen less frequently with a quality elbow that’s suitable for your pneumatic conveying system, meaning less downtime and better customer service. It’s also important to take into consideration how long it takes to replace an elbow in your system – it could be a matter of minutes, or you may need to hire a crane in order and get somewhere hard to reach to make the repair.

Impact on Production

In some cases, the impact on the production line is more serious than downtime. A blown elbow could mean a contamination issue from a ruptured system, and you may also need to factor in clean-up costs and the time it takes to reset after a blown elbow.

Consider purchasing a high-quality elbow that suits your system requirements and is less likely to blow and cause this type of damage. This is an especially important consideration when you’re manufacturing highly reactive products in non-air systems.

Safety Considerations

That leads us on to safety. If you’re manufacturing a product which you do not want in the atmosphere or which is environmentally unsound, hard to cleanup chemicals, for example, you need the best-matched abrasion resistant elbow for your system. It will be important to plan in advance the replacement of elbows that are conveying environmentally unsound materials to prevent this from occurring.

Planning to Replace an Elbow

From a lean manufacturing perspective, planned downtime is infinitely better than unplanned downtime. Instead of waiting for an elbow to blow, you could check the thickness of the wall with a sonic device to determine the likelihood of needing a replacement part. It’s also a good idea to have a replacement elbow spare, so if one does blow it can be replaced quickly.

If you know from experience how long your elbows generally last, you can also plan to replace them in advance where you can assume significant wear has occurred.

Customer Example: Replacing an Elbow with a Progressive Products Abrasion Resistant Elbow

One of our customers used an elbow that was not considered abrasion resistant, and the product they were manufacturing was an extremely abrasive powder. Because of the safety risks involved, they were only manufacturing their product for two week periods before renewing their equipment to ensure that everything was in good working order. This resulted in an unacceptable amount of downtime and missed business opportunities.

When they came to us we saw that the elbows they were using weren’t right for their needs, and we recommended a simpler solution which fulfilled their needs and saved them a significant amount of money by decreasing their manufacturing downtime.

A Final Thought

It’s really important to look for a solution that’s right for your needs and speak to companies with knowledge, expertise, and experience who offer a range of products for you to choose from. It goes the other way as well – you may not need the most expensive solution as it may just be overkill for your requirements.

At Progressive Products, we won’t sell you anything you don’t need – we’ll sell you the best quality solution that’s right for your system. Contact us today to find the right solution for you.

Download Our Guide to Elbows, Now!

If you like what you’ve read, we have a PDF version you can take with you.