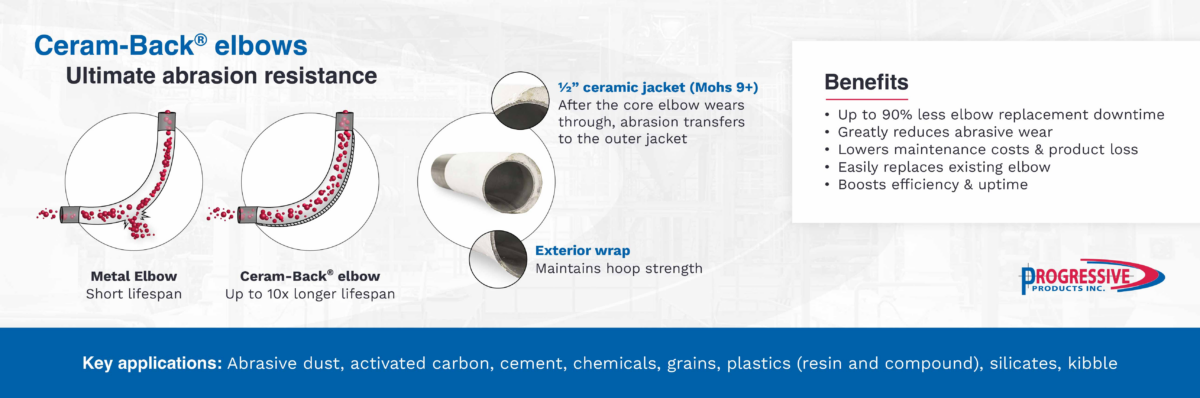

Ceram-Back® Elbows

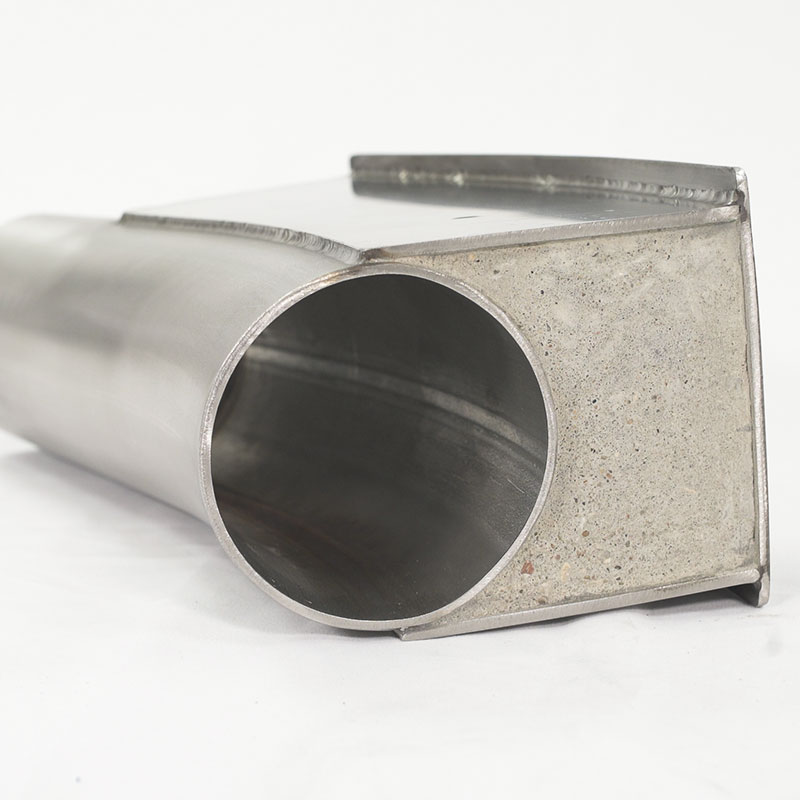

The patented Ceram-Back® elbow has a jacket across the back of a bare or core elbow which is approximately ½” of ceramic compound. This compound has a Mohs hardness of 9+, second only to diamond which has a Mohs hardness of 10. The ceramic jacket and core elbow are then wrapped with an exterior material to maintain hoop strength. Once the core elbow has worn through, abrasion is then transferred to the ceramic outer jacket, therefore increasing the life of your elbow. The metal core also acts as a static conductor.

Designed to eliminate unwanted costs such as maintenance, loss of material, and system downtime, abrasion-resistant Ceram-Back® elbows easily replace the conventional elbow without changing the line flow and are manufactured to remain in a pneumatic conveying system much longer. This means you can:

- Reduce costs

- Improve efficiency

- Increase production

Ceram-Back® elbows are available in:

- Any degree and centerline radius (CLR)

- Carbon steel, stainless steel, aluminum, and galvanized steel

- Pipe and tube

- Plain ends, flanged ends, grooved ends, and other specified ends

There is very little a Ceram-Back® elbow can’t do, and they’re used across a wide variety of industries from grain and pet food to plastics. These elbows are most commonly used to convey abrasive dust, activated carbon, cement, chemicals, grains, plastics (resin and compound), and silicates.

How Ceram-Back® elbows work

After abrasive wear degrades the core elbow, your materials come into contact with the Ceram-Back® backing. This is significantly harder and more abrasion resistant, and takes up to 10x longer to wear through compared to a conventional elbow.

Ceram-Back® elbows remain in your system far longer despite continuous wear, reducing elbow replacement downtime by up to 90%. In fact, each Ceram-Back® elbow can lead to a return on investment of $4,805 over four years compared to a carbon steel pipe elbow.