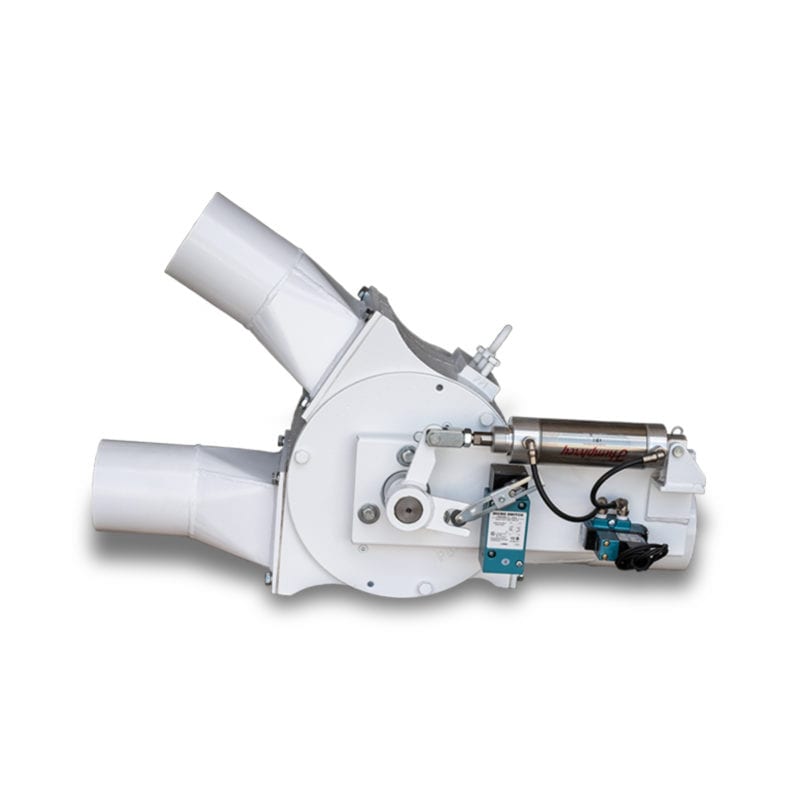

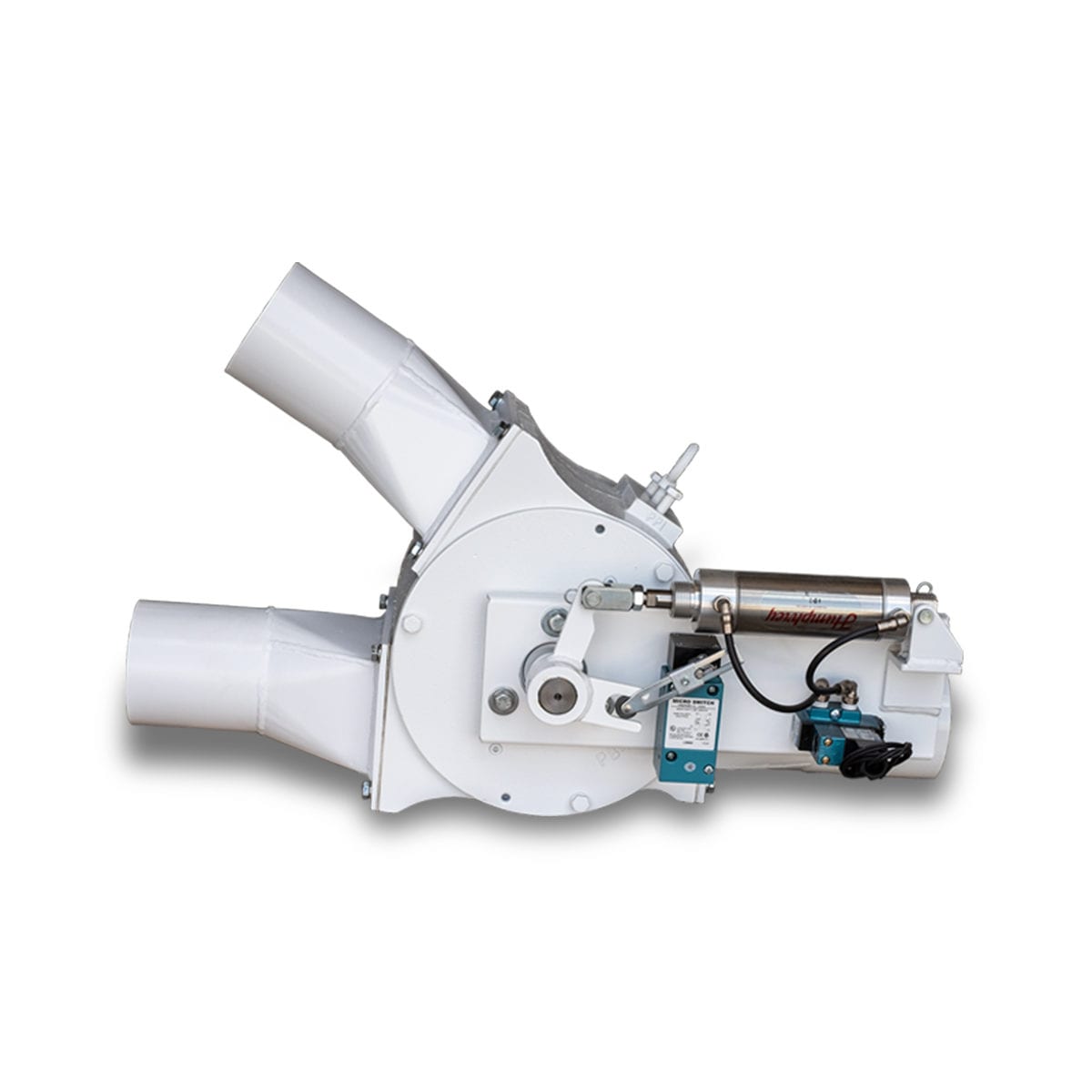

Diverter Valves

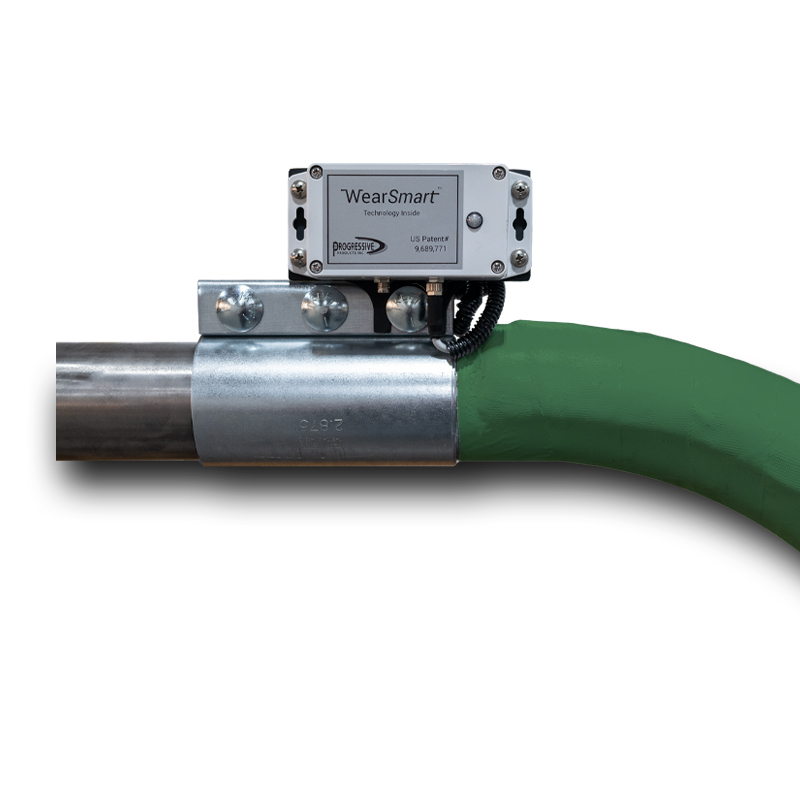

Progressive Products Inc. manufactures heavy-duty diverter valves designed to manage continuous material flow while efficiently redirecting product with minimal pressure loss. Built for reliability in pneumatic conveying systems, our diverter valves allow material to be re-routed from one location to another without disrupting system performance.

We offer two primary diverter valve configurations to suit different applications. The Line Diverter Valve Series is ideal for products that are not highly abrasive and do not smear, while the Tunnel Diverter Valve Series is designed for applications where a line diverter cannot be used or where two conveying lines must be combined into one. Each option delivers dependable operation tailored to your system requirements.

- Prevent contamination

- Operates at line pressures up to 15 psi

- Two-way switching capability

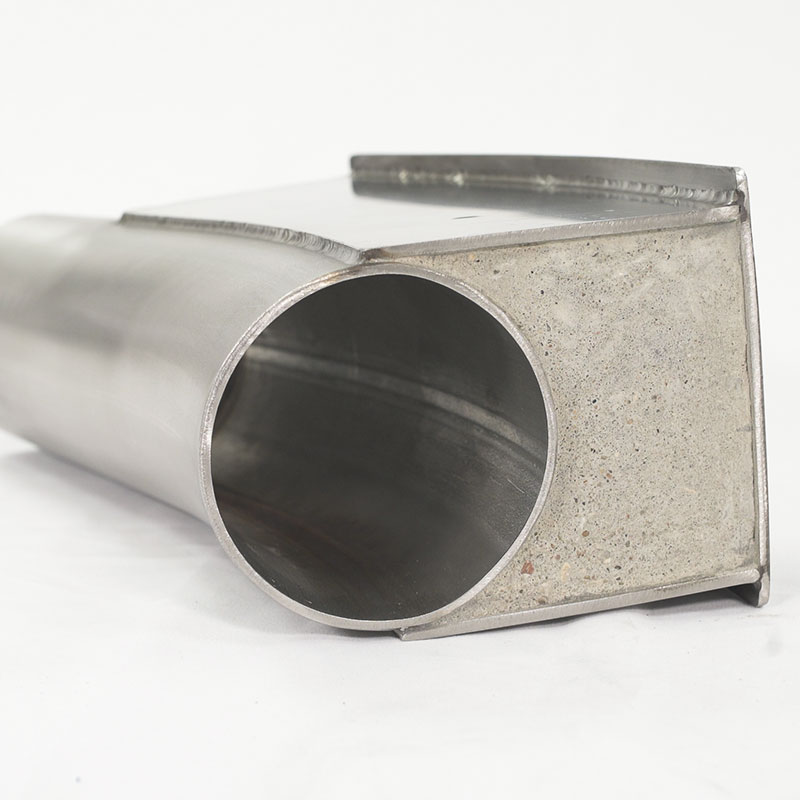

- Precision-machined cast iron housing and endplates

- Precision-machined carbon steel rotor for holding pressure

- Lifetime food-grade lubricated and sealed ball bearing with eccentric locking collar

- Shaft sealed for maximum leakage resistance up to 15 PSIG pressure differential

- End plates, seals, and bearing protected from material flow by rotor end platers and special food-grade lubricant packed into the void area between the end plates and rotor hub

- Air-operated rotary actuator with a 4-way single solenoid valve, and switch assembly consisting of two Single Pole, Double Throw (SPDT) limit switches to proof both positions of the valve

- Optional features:

- Double solenoid air control valve

- Manual or electric actuators

- NEMA 7/0 electrical enclosures

- Ceramic-coated tube adapters

- Factory pre-wiring of solenoid and limit switches to terminal box

Suitable for any dry bulk material application, particularly:

- Hygienic transportation of food and beverages

- Safe transportation of fragile materials

- Materials that tend to clog

- Abrasive materials