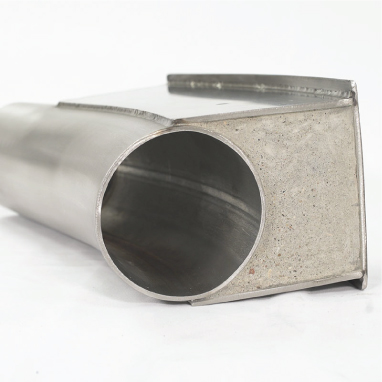

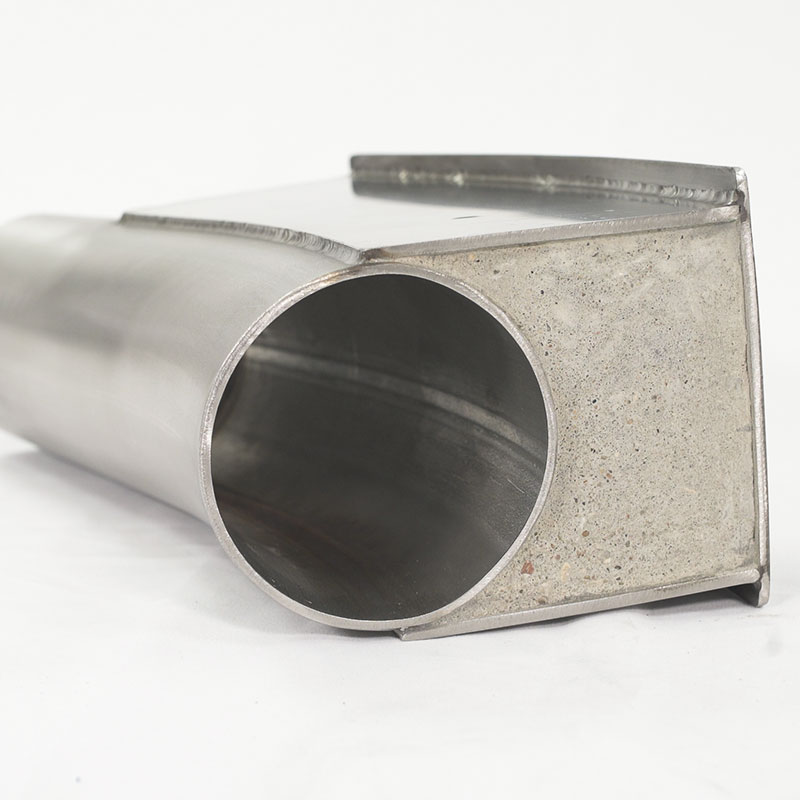

Mortar-Filled Flat-Back Elbows (Cement-Back)

As the name suggests, a mortar-filled flat-back elbow has a cavity that’s backfilled with hard concrete. A standard or custom mix concrete can be used, and the metal exterior can be constructed out of various thicknesses of materials. For high heat applications, refractory can be used instead of cement.

Fabricated using a tube or pipe elbow to eliminate transitions, the back cavity is filled with a hard concrete to extend the life of the elbow when the bare or core elbow has blown out by the conveying of abrasive products.

These types of elbows have a thicker back than cast ceramic flat-back elbows and lie somewhere in between Ceram-Back® elbows and flat-backs in terms of abrasion-resistance.

If you use refractory backing instead of cement backing, you will find the elbow is more resistant to heat and abrasion. Refractory backing is very hard, and while it isn’t quite as hard as tile it does have the advantage of being cheaper.

Cement-back elbows are available in:

- Any size, degree, and bendable centerline radius (CLR)

- Carbon steel and stainless steel

- Pipe and tube

- Plain ends, flanged ends, grooved ends, and other specified ends

You can also request customized mortar-filled flat-back elbows – just speak to one of our experts about your exact requirements.

Mortar-filled flat-backs are most commonly used in heavy industry to convey abrasive dust, coal fines, fly ash, fine silicates, and portland cement. Their main use is in cement plants, as you clearly can’t contaminate cement with cement. Cement-backs are also used to convey grain and rice whorls.