Airlocks

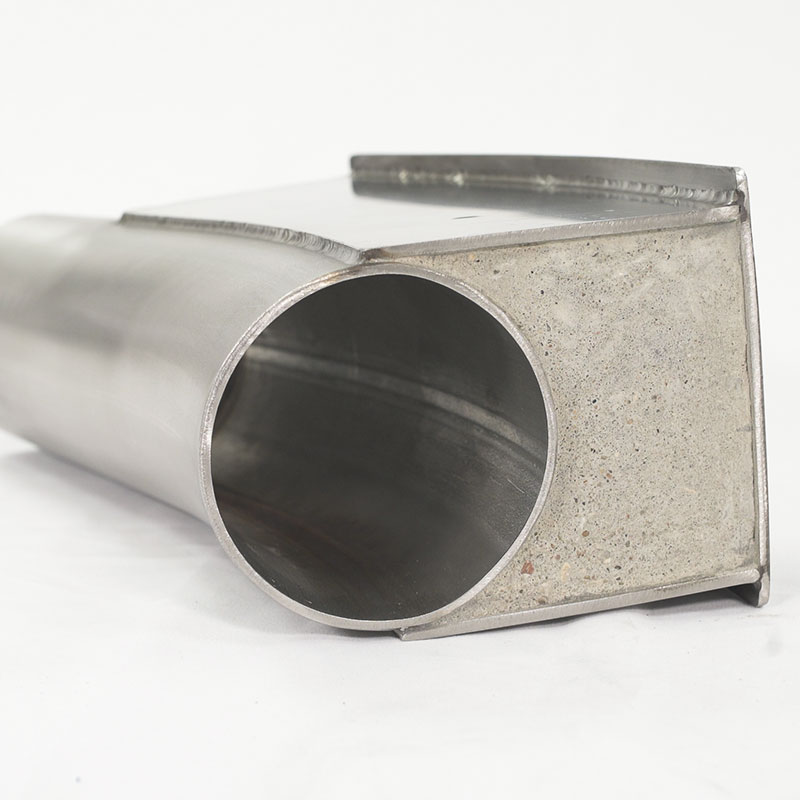

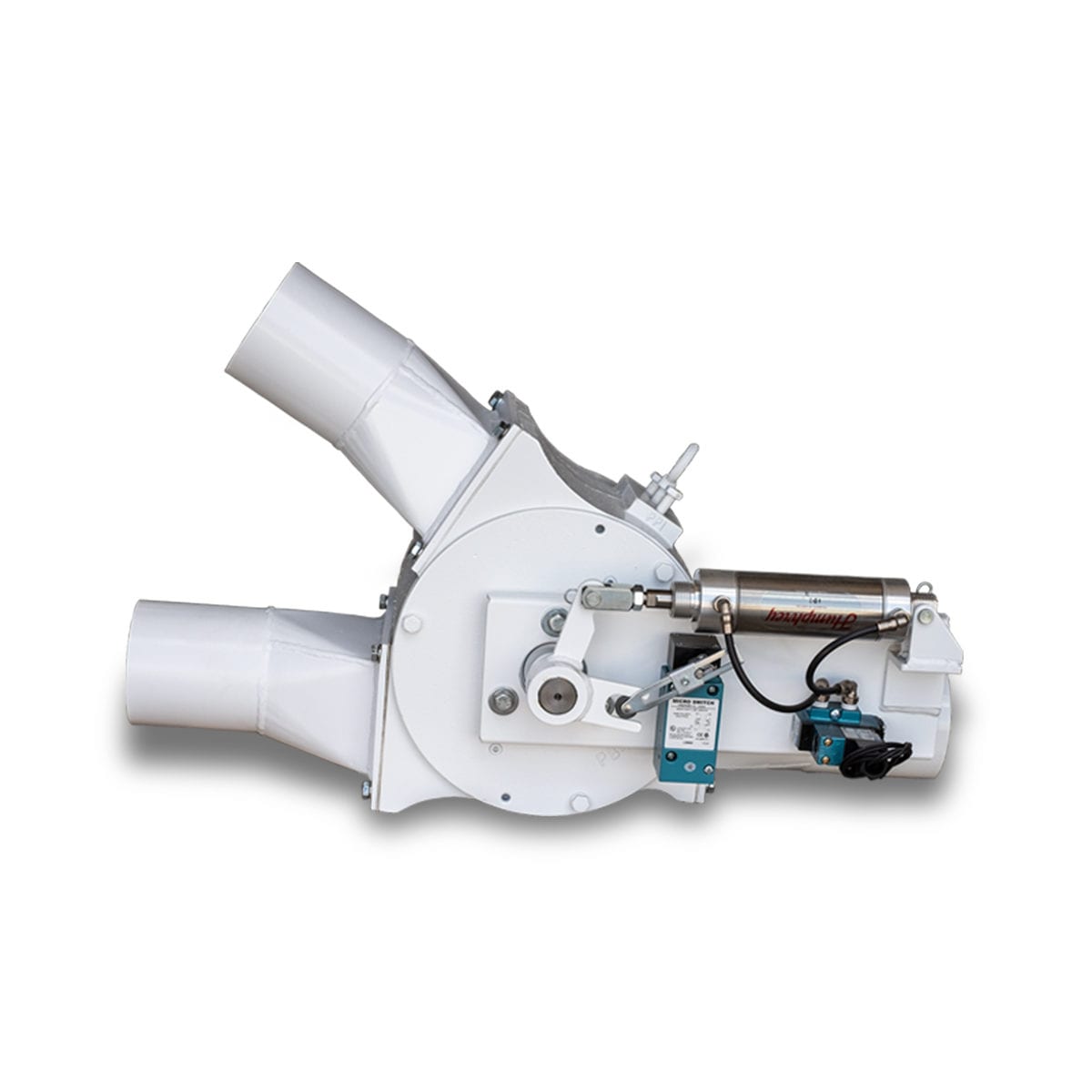

Our airlocks for pneumatic conveying systems come in three sizes and four configurations. At 8”, our smallest valve has .004”-.005” end clearances and .003”-.005” diameter clearances. Configurations include standard construction, mildly abrasive service, corrosion-resistant service, and moderate abrasive service.

Each airlock features outboard bearings and seals, rotors with relieved tips and sides, and tapped endplates. Standard seal is a compression-type design that requires no field adjustments and is maintenance-free for the life of the seal. Airlocks are also available with T-seals for top performance in severe operating conditions.

- No field adjustments

- Tight tolerances

- Maintenance-free for the life of the seal

- Connect to many types of conveying equipment

- Very reliable

- Tightest tolerances – smallest valve (8”) has .004”-.005” end clearances and .003”-.005” diameter clearances

- Holds at least a 20 PSI pressure differential

- Configurations for standard, mildly abrasive, corrosion-resistant, and moderately abrasive services available

- Cast iron housing

- Three-sided rotor relief for better revolution accuracy and less wear

- Outboard bearings that remain free of material

- Standard seal is a maintenance-free compression-type seal that requires no field adjustments

- Optional Teflon seal for extra-long life

- T-seals available for severe operating conditions

- Squeeze Lock bearing for easy servicing

- Oversized rotor shaft to prevent twisting

- Air-purge ready

- Wide range of options and accessories available

- Silo emptying

- Cyclone discharging

- Dust collection

- Dosage control, mixing, and batching

- Conveyor feeding or discharge

- Bulk solid filling

Suitable for any dry bulk material, including:

- Abrasive dust

- Ash

- Cement

- Chemicals

- Grain

- Kibble

- Particulate foods

- Plastics

- Sawdust